Mechanical Characterization

In order to assess material behavior under realistic working conditions, the KTP offers a comprehensive range of testing options to for the characterization of mechanical behavior. Depending on the issue at hand, we can offer support with the following test methods:

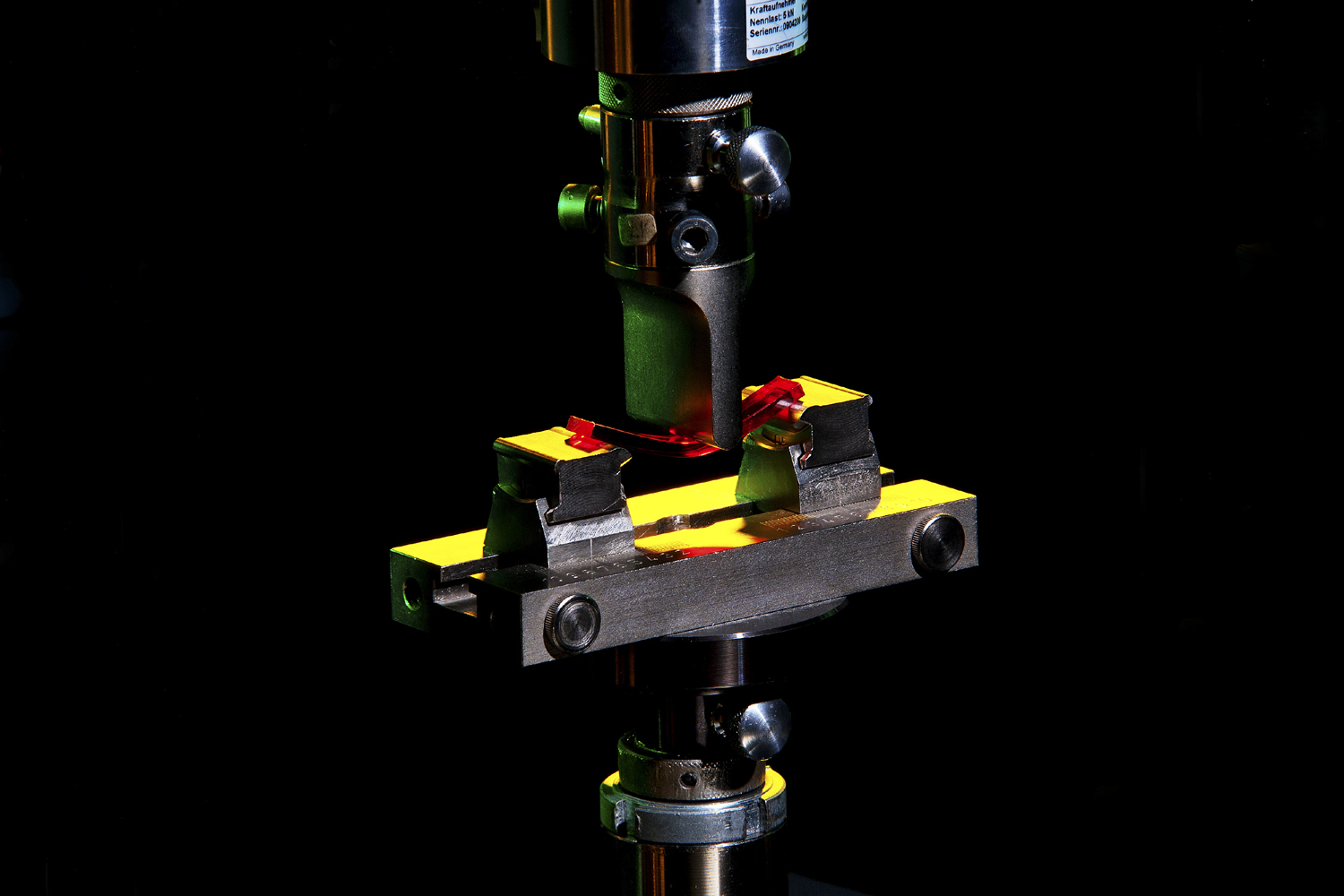

The universal testing machine in our test laboratory allows us to simulate any kind of mechanical loading on a given specimen, such as tensile , bending, compression, or peel loading. This procedure helps determine relevant parameters such as the modulus of elasticity. It further predicts material behavior under certain loading conditions.

To characterize plastic elements in terms of their impact behavior,, specimens are clamped in our dart drop testing device and subjected to mechanical impact from a maximum drop height of 3 meters. In addition, we can also offer impact testing with our Charpy impact testing machine. These tests allow us to determine the impact resistance of the sample specimens under sudden loads.

In the field of composite or multi-material component characterization, the friction coefficient, for example, of a screw thread or another friction-locking section of a plastic component can be determined experimentally. The functional reliability of your component in such assemblages can be determined at a dedicated screw-joint testing station.

Your specimen is prepared for testing by our employees using a specimen punch or a milling machine for the respective test device according to the appropriate industrial standards.