Additive manufacturing processes

Together with other chairs in the Faculty of Mechanical Engineering, Paderborn Plastics Technology is an integral part of the Direct Manufacturing Research Centre (DMRC). The DMRC focuses on additive manufacturing processes that are used to produce components, known as direct manufacturing, and represent an important technology of the future. This new type of manufacturing promises significant advantages over conventional processes, such as reduced production and process costs, shorter throughput times, more complex component geometries or the demand-orientated production of components and spare parts. The aim of the DMRC is to further develop additive manufacturing processes and the components produced in this way until they are ready for series production.

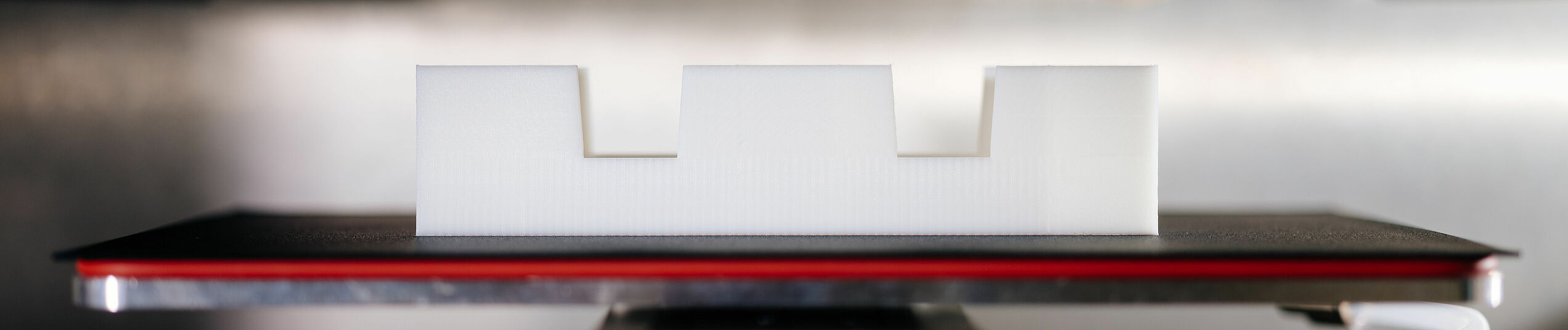

Additive manufacturing processes are characterised by the fact that the components are usually produced by adding or joining solid elements layer by layer. The virtual component, which must be available as a 3D CAD data set, is first broken down into layers of equal thickness and then converted layer by layer into a physical component. The production of components can be realised using various physical principles. However, the fundamentals of each process are identical. The following processes are being researched at the DMRC:

- Selective Laser Melting (SLM)

- Laser-Sintering (LS)

- Fused Deposition Modelling (FDM)

Research focuses on process optimisation and cross-process topics such as design guidelines, costs and strategic aspects of additive manufacturing processes.