Recycling plastics - A necessity

Against the background of polluted oceans (microplastics) and the increasing consumption of resources in all parts of the world with the simultaneous finite nature of natural resources, resource efficiency and the circular economy are gaining in importance in today's world. Both in politics and industry as well as within society, a rethinking is taking place regarding the sustainable use of resources. This is increasingly becoming the core task of the 21st century.

We at KTP are aware of the responsibility and are taking up the task.

Recycling of plastics waste in Germany

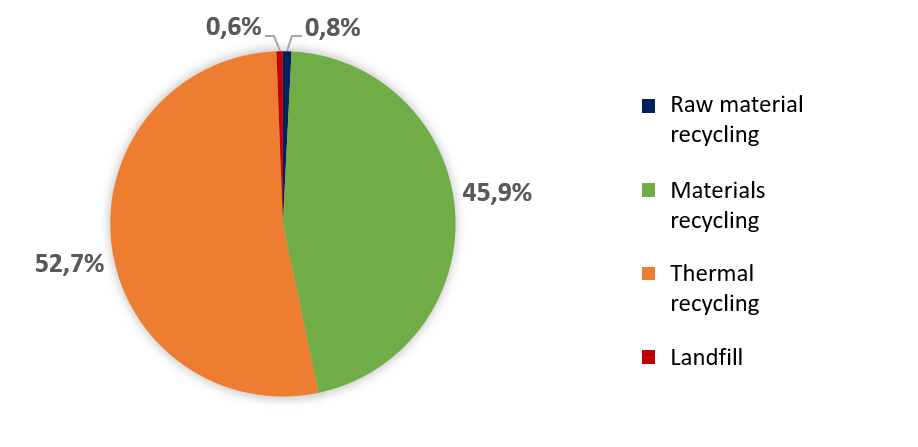

To date, more than half of all plastic waste is thermally recycled. According to the Closed Substance Cycle Waste Management Act, both mechanical recycling and feedstock recycling are preferable. This is because the ecological benefit of the product increases with each recycling.

In the course of the research project, an innovative back pressure length control system was developed to avoid process fluctuations in thermoforming extruders with a high recycling content. One sub-project objective included the development of a soft sensor that is used as the core element for the backlog length control and can detect it accordingly in the process. The back pressure length, also known as the filling length, occurs in extrusion processes with a degassing zone. The latter is required for the escape of volatile components (e.g.: water vapours, residual monomers and other volatile impurities), as is the case, for example, with recycled materials that are often still printed. In order to allow the volatile components to escape, the screw must be partially filled at this point, which is achieved by a back pressure stage with a sudden increase in the channel volume. The resulting back pressure length depends in particular on the back pressure induced by the pressure flow of the mould and on the recyclate content of the material to be processed.

Furthermore, the project optimised the feed geometry of the high-speed extruder so that regrinds that tend to bridge can be conveyed more consistently in the solids area and correspondingly higher throughputs can be achieved. In addition, the degassing performance was improved as a further sub-project objective by optimising the degassing opening in order to be able to meet higher requirements for high-quality recycling products.

The aim of this project is to develop a plant for the direct processing of recycled plastic flakes. By using this technology, the quality of the recycled end product should be increased, in addition to increasing the recycling rate, in order to ultimately be able to manufacture products with high quality requirements completely from recycled material. In this process, the recyclate as a starting material in the form of so-called flakes (shredded plastic parts) is first formed into finger-sized agglomerates in an agglomeration step. In an agglomerator, a feed screw compresses the plastic flakes and conveys them between the pair of discs of the agglomerator. The latter consists of a rotor disc, which performs a rotating movement, and a stator disc, which serves as a counter element and does not rotate. The kneading and rolling of the plastic flakes between the discs generates frictional heat, which plasticises, sinter and densifies the material. In contrast to extrusion, the melting point of the material is not reached, as it is only brought into a pasty state. The aim of the project is to develop the pair of discs of the agglomerator in such a way that a defined and constant agglomerate size is realised and these agglomerates can be fed directly to a single-screw extruder and immediately processed into a product.

A major challenge in the mechanical recycling of fibre-reinforced end-of-life products is the fibre dust produced during shredding. This consists of potentially respirable fibre fragments, which can also have WHO fibre characteristics. WHO fibres are fibres with a diameter <3 µm, a length >5 µm and a length-to-diameter ratio of >3:1. They can be formed by splicing glass or carbon fibres under mechanical stress and can be potentially toxic. The aim of the research project was therefore to investigate the formation of WHO fibres or alveolar dust fractions during the mechanical recycling of thermoplastic fibre-reinforced plastics and to analyse their toxicity. Furthermore, the formation of alveolar dust should be reduced through a targeted optimisation of the parameters in the comminution process.

Investigations on the granulator and the single-shaft shredder have shown an increase in the respirable fibre dust fraction with increasing rotor speed, as well as with decreasing screen mesh size. Even though a concentration of respirable fibre fragments exceeding the limit value could be measured in some cases, especially for the carbon fibre-reinforced organic sheets, no toxic effect was determined.

In applications that require special material properties that cannot be fulfilled by standard plastics, engineering plastics are used. Often, engineering plastics are characterised by better mechanical properties than standard plastics. However, other characteristics can also be decisive for their use instead of a standard plastic. The special properties of engineering plastics are accompanied by a higher material price. This value of engineering plastics is a reason to recycle the materials. Furthermore, recycling avoids plastic waste and the energy-intensive production of virgin material.

In this research project, technical plastics are to be recycled by producing fibre-reinforced compounds from the plastics. The compounds are to achieve almost the same properties as compounds made from virgin material, so that they can also be used in demanding applications.

Compound development takes place on co-rotating twin-screw extruders. These have a high mixing effect and are therefore particularly suitable for incorporating the fibres into the plastic melt.

Due to the fact that the plastics to be reused are mixed with additives that were beneficial in the original application and that no grade purity is guaranteed for plastic waste, two challenges arise that do not exist in compound production from virgin material. Firstly, mixtures of different plastics and additives are more difficult to process than firmly defined formulations of virgin material and known additive mixtures. Secondly, the waste materials used may contain plastics that are incompatible with each other. These difficulties must be taken into account during material development and overcome by using additives.