Extrusion

Varying styles of extrusion processes are represented in the KTP’s research. An extensive array of machinery is available for this research, consisting of a variety of different extruders as well as “downstream” process equipment from numerous different manufacturers. Our fields of interest range from general process design to detailed component and product design. For such tasks, our in-house software “REX”, for single-screw extruders, and “SIGMA”, for twin-screw extruders, are used.

The following lists a selection of research topics from our group:

Single-Screw Extrusion

- decomposition behavior of polymers

- feed intake optimization

- high-speed extrusion

- rubber processing

- simulation and modeling

Twin-Screw Extrusion

- compounding process

- simulation and modeling

Downstream Processing

- flat film and blown film

- granulation

- stretching

- pipe/tube extrusion

For further information about individual extrusion topics, please contact the appropriate person (see right side bar).

In addition to conveying and homogenising, the task of a single-screw plasticising extruder is to convert the plastics to be processed from a solid to a molten state. In this process, the plastic, which is present as granulate, powder or regrind, is melted under the influence of heat conduction through the barrel as well as by dissipation in order to continuously increase the melt content along the screw channel. On the one hand, the aim is to completely melt the plastic in time to ensure subsequent thermal and material homogenisation of the melt produced within the remaining process length. On the other hand, complete melting should not take place too early in relation to the screw length, as otherwise the melt will be thermally damaged. Only in this way can qualitatively perfect products be produced in the downstream equipment of the extruder. In order to be able to predict the required melting length mathematically, a number of models have been developed in the past. In most cases it is assumed that a film of melt forms between the compacted solid and the heated barrel, which is scraped off the screw flight when the radial thickness is sufficient and flows into the so-called melt vortex.

The aim of this research project is to improve the calculation accuracy of the melting behaviour in single-screw extruders with special consideration of the mechanics of the solids bed. This is to be done by addressing two questions that have so far been insufficiently clarified at the theoretical level: One is the question of how the velocity of the solids bed in compression zones of single-screw extruders changes if the validity of the melting model according to MADDOCK is assumed. For this purpose, experimental investigations are carried out in which the solids bed velocity is specifically influenced with the aid of different screw geometries and pellet dimensions. On the other hand, the question arises as to when the range of validity of this model ends depending on the process parameters and a disperse melting model must be assumed instead.

Single-screw extrusion is one of the most important processing methods for thermoplastics in terms of volume. In the design of grooved barrel extruders, simulation is a common means of saving costs for experimental investigations in a trial-and-error process. However, existing calculation methods based on analytical equations are subject to some assumptions and simplifications. Therefore, the aim of this research project was to review the existing calculation approaches with the help of numerical simulations of the discrete element method (DEM) and to develop an adapted modelling. First of all, the necessary material properties were determined for three exemplary plastics and a simulation model was worked out together with the necessary setting parameters. For this purpose, friction values and granulate dimensions were determined and an initial comparison between simulation and experiment was carried out. The following served as benchmarks

throughput and compression tests served as benchmarks. The selected simulation settings led to predominantly good agreements. Furthermore, a test rig was developed to investigate solids handling in grooved feed zones in isolation and with a counterpressure. By means of a statistical test plan, a broad database was generated with the DEM simulation model, which allowed a systematic comparison with existing modelling approaches and experimental investigations. It was shown that the assumptions of existing analytical approaches are mostly justified. These include the assumption of a backpressure-independent throughput and the division of solids transport into so-called transport cases. Existing deviations could be reduced with the help of a newly defined, regressed correction factor. Finally, the validation with the help of the newly constructed trainer also shows good agreement between the simulations, analytical calculations and the experimental investigations.

The aim of the project is to use cyber-physical systems on a profile extrusion line to automatically recognise the condition of the line (in terms of process robustness, efficiency, quality, productivity) and to develop optimisation options automatically by the system.

In a first step, these optimisation options are to be visualised for the machine operator and, in a second step, used in a higher-level control system to autonomously influence the process. For this purpose, all information describing the process is first to be collected via physical sensors. For this purpose, the known information is exported to an external database and at the same time further sensor information is recorded on the line and its result data is also exported to this central database. Thus, the actual live information of the process is available in a digital system and can be further processed there.

To determine further information that cannot be measured via real physical sensors, for example, three computer simulations that are completely separate from each other and have not been combined so far are automated independently of each other and enabled for live operation. First among these is the KTP's REX simulation software, which can calculate the entire operating behaviour of the extruder on the basis of the live process data. In second place comes the simulation software Extrud3DPro from the project partner IANUS, which generates further results on the basis of the live process data and the results from the extruder simulation. In third place comes the cooling simulation chillWARE from the project partner SHS plus, which in turn uses the live process data, the result data from the extruder simulation and the tool simulation based on it as input parameters. In a final step, the simulated information is combined with expert knowledge and optimisation potential is suggested.

In the field of mechanical and plant engineering, the lubrication of machine elements such as gears and bearings represents a central challenge in order to reduce friction and wear between the machine elements and to extend the service life of the components. For this purpose, so-called lubrication gears or lubrication pinions were developed, which only serve to apply the lubricant, but not to transmit torques. The use of both synthetic and mineral oil-based lubricants is usually overdosed in order to ensure the safety of the lubrication. This means that the surplus, which is usually harmful to the environment, is allowed to drip off and contaminate the environment, especially in open gears. Nevertheless, a lack of lubricant also leads to increased friction and noise levels as well as increased abrasion and thus resource consumption.

For this reason, the aim of the project is to design and develop a control system that applies a defined quantity of lubricant through a lubrication pinion as required, whereby the quantity of lubricant present at the lubrication point is measured and compared with a previously determined minimum value. External influencing variables such as temperature, humidity and contamination of the environment, which can influence the buffer and delivery behaviour of the lubrication pinion or the viscosity of the lubricant, must be taken into account during the control.

Both the lubricants and the materials of the pinion are analysed and selected according to the application. The control system for relubrication as well as the lubricant pumps required for this are analysed for a solution available on the market and, if not, developed independently. The focus is initially on open gears, as this area of application is particularly exposed to the environmental influences mentioned and consequently the stress on the system is very high.

The overriding goal is to prevent the overdosing of lubricants and thus to bring an economical and environmentally friendly development to the market.

Single-screw extrusion is one of the core competencies in plastics processing. Against the background of economic conditions, increasing the throughput of processing machines while maintaining a high melt quality is one of the primary development goals of many machine manufacturers. This requires a targeted screw design.

In the intended research proposal, the correlation between the processing parameters and the melt and product quality is to be investigated on the basis of an extruded pipe profile. The aim is to identify a quality limit above which the melt quality at the extruder outlet is no longer sufficient to be able to extrude a high-quality product. This quality limit is to be considered primarily as a function of the location of the melt end in the extruder, but other influencing variables are also to be taken into account. In the preliminary investigations, both relevant and non-relevant influencing factors are to be identified in order to draw up a selection of factors to be investigated on the basis of the results. In addition, the influence of different common extruder screws is considered. The selected influencing factors are then systematically investigated to the required extent. The experimental investigations are analytically simulated with the corresponding process parameters and the simulations are validated using the experimentally generated data. The simulations allow an insight into the processes in the extruder, such as determining the location of the melting end.

The aim of the investigations is to develop a model which, based on the processing parameters and analytically feasible simulations, enables a prediction to be made about the expected melt quality at the extruder outlet. The aim is to provide a tool for screw design that can quickly and cost-effectively check the requirements placed on the screw to be designed.

In the plastics processing industry, the focus is increasingly on optimising the economic efficiency of extrusion lines. In order to ensure a sufficiently high melt quality at higher speeds, new screw concepts are therefore being developed in addition to conventional screws, although these have not yet been fully researched. Particularly worthy of mention here are the "solids-bed-breaking" screws, which promise an increased throughput while maintaining the same melt quality. These include, for example, wave or energy transfer screws. In addition to the economic operation of the plants, many companies are increasingly focusing on simulations of newly designed screws or plants in order to reduce costs. The basis of such simulation software are mathematical models that correctly reproduce the process sequences. However, there is still a need for research in this area for new screw concepts, especially for treated solid-bed breaking screws. Initial models of both the melting and the pressure-throughput behaviour of these have been developed, but they still need to be optimised further. The homogenisation processes that take place as a function of the screw geometry or process-relevant influencing variables can also only be described mathematically to a limited extent.

However, since there are hardly any empirical values for the design of energy transfer screws, the aim of this research project is to investigate the process behaviour of energy transfer screws by means of numerical simulations, which take into account the melting of the plastic and have been optimised for the application, and experimental test plans. By means of a simulative test plan, a screw optimisation for different plastic types is carried out. A comparison of six existing energy transfer screws will be carried out experimentally in order to validate the design procedure by means of the simulative test plan and thus subsequently provide design guidelines for energy transfer screws.

The objective of the research project is to develop recommendations for the gentle processing of polypropylene on the twin-screw extruder and thus to enable time and cost reductions for the user.

In the run-up to the material degradation tests, a reproducibility analysis was carried out. This ensured the reliability of the results by determining the measurement and process scatter. In order to be able to determine the effect of the previously defined influencing variables on the degradation behaviour, a full-factorial test plan was created and run on a twin-screw extruder. The samples produced were then examined with regard to their melt flow rate and this in turn was mathematically converted into the weight-average molecular weight. It was found that high rotational speeds, low throughputs and high melt temperatures increase material degradation. Compared to these factors, the screw configuration has little influence on the degradation behaviour. For the user, this means that almost any screw element can be used after the melting zone. Since consistent effects on material degradation were found for two polypropylene types with different flow behaviour, it can be assumed that the recommendations for action are generally valid for polypropylene. The results obtained were verified in a further investigation using gel permeation chromatography (GPC). This enabled the additional analysis of the molecular mass distributions. For the mathematical description of the material degradation, the model developed by Littek et al. for the single-screw extruder was modified. It enables the determination of the molar mass reduction as a function of the parameters shear rate, residence time and temperature. The mean percentage deviation of the modelled molar mass ratios from the molar mass ratios previously determined using the MFR values is 7.15%. The developed model thus provides a good prediction of the material degradation of polypropylene on the twin screw extruder and was therefore implemented in the SIGMA simulation software. For the future, an extension of the model to industrial machine sizes and different PP compounds is planned.

When heating and incorporating additives into plastics in a co-rotating twin-screw extruder, it is important to ensure that the plastic is not heated above the decomposition temperature and thus damaged. Up to now, it has only been possible to estimate the average energy input via the two screws from the power applied by the motor. However, different screw profiles occur along the extruder, which consume different amounts of energy and introduce it into the material. Local excesses of the decomposition temperature would not be taken into account in this approach.

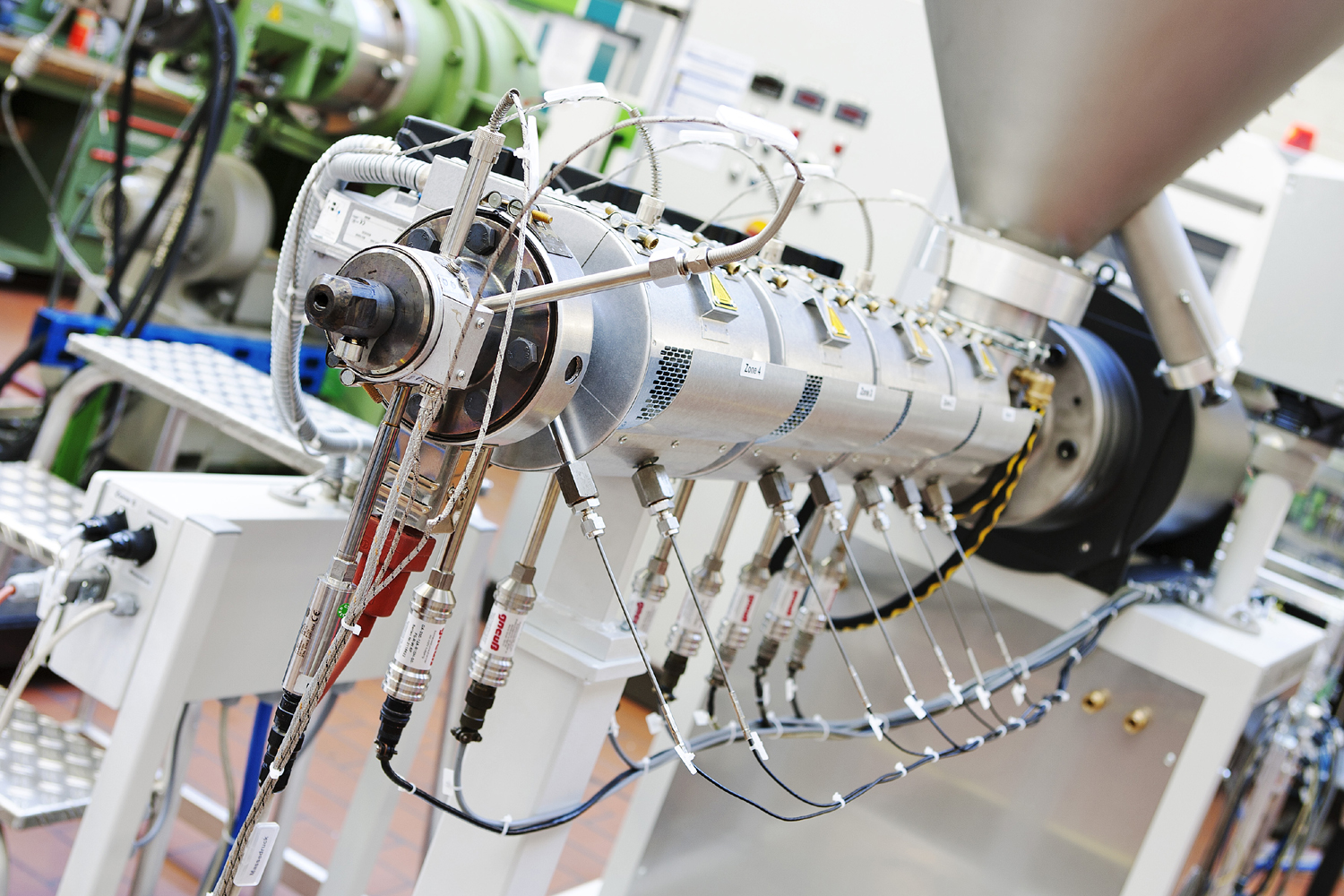

The aim of the research project is to develop a model that can map the energy input over the extruder length with axial spatial resolution. The metered operation of twin-screw extruders poses a challenge in this context, since in partially filled areas it is also necessary to differentiate between the two screws, since they are filled differently and cause different energy inputs. The basis for the project is the relationship between the flow resistance of the melt against the screws and energy input, which can be determined via the torsion and the required torque. For this purpose, the position of the screw flights on the element under the sensor is determined using different sensor concepts in the degassing insert of the twin-screw extruder. This position is compared with another measuring point. The resulting phase difference can be used to determine the torsion of the screw caused by the melt.

The sensors continuously record the position of the screw flight. If the signals are congruent, there is no torsion of the shaft. The greater the phase difference, the higher the load on the screw under consideration. Based on the measurements, a mathematical model is subsequently built on physical relationships, which is integrated into SIGMA to simulate the specific energy input along the extruder.

The process for producing laser sintering powder researched in this project is the PGSS process ("Particle from Gas Saturated Solutions"). In this process, plastic is plasticised and a supercritical fluid, such as CO2 , is added. This reduces the viscosity of the melt to such an extent that the plastic-gas mixture can be sprayed and disintegrates into powder particles during the resulting relaxation.

When the dispersion is sprayed, the supercritical CO2 again assumes a purely gaseous state, whereby it expands and thus increases in volume. As a result, the gas dissolves out of the plastic phase and breaks it apart. The resulting particles form a sphere during the fall due to the surface tension of the polymer. At the same time, these spherical particles are strongly cooled and solidified by the Joule-Thomson effect that occurs during the expansion of a gas. The final result should be a laser sintering powder with ideally spherical plastic particles and thus good flowability.