Injection Molding

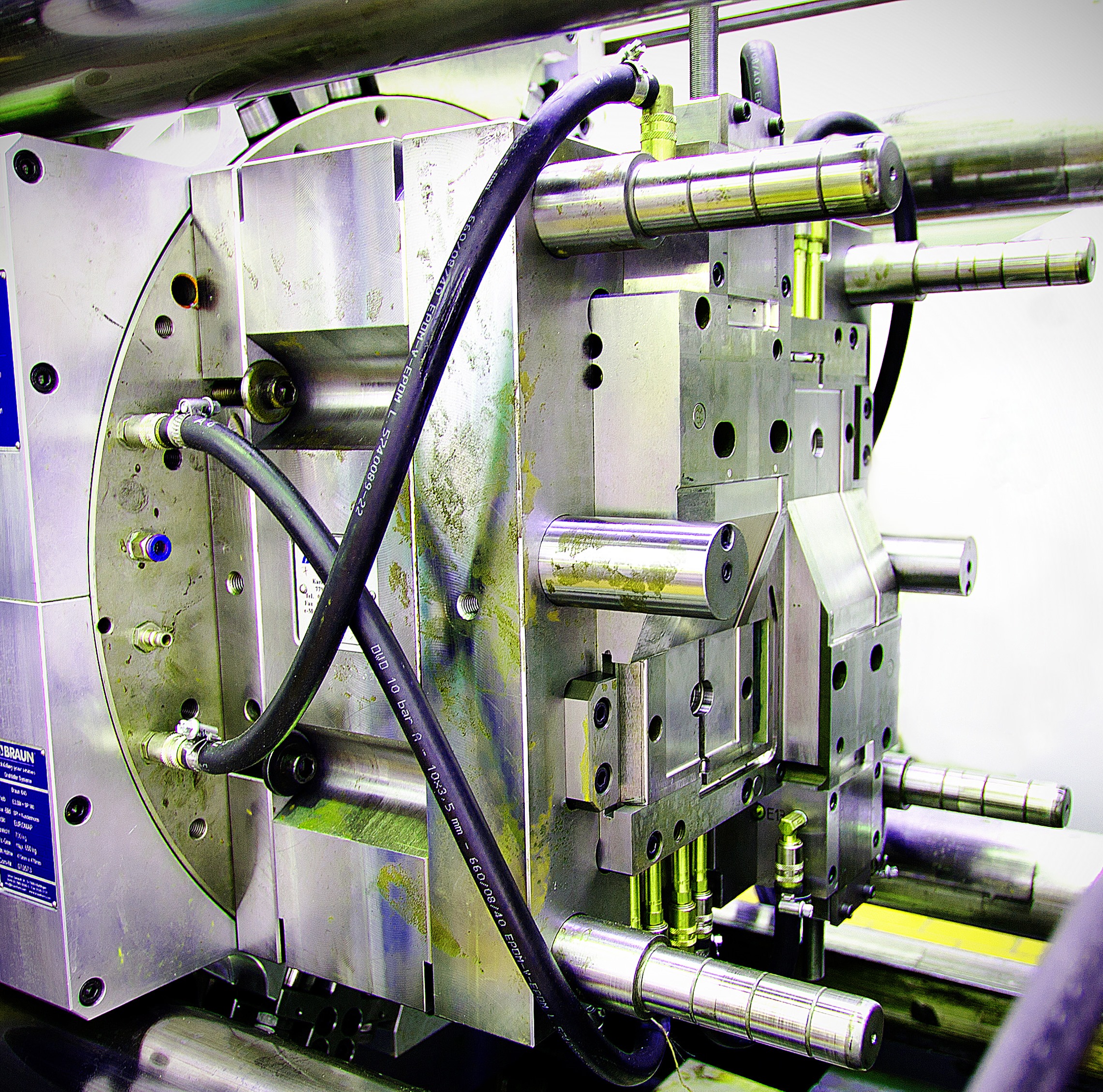

Since its inception, the Kunststofftechnik Paderborn has concerned itself with injection molding, which is, next to extrusion, the most commonly employed method of plastics processing. In addition to the conventional single-component injection molding, specialized injection molding processes have been and are being researched, such as 2-componentcomposite material injection, sandwich-molding, gas injection technology (GIT), and the GITBlow process, which was developed at the KTP. Apart from process engineering of injection molding, additional foci of our activities are the fill characteristics in the tool and tool technology.

The following is an extract of our research foci in this area:

GITBlow

- process optimization

- simulation of the blow process

- material compatibility

Tool Technology

- development of coatings to reduce de-molding forces

- development of in-mold riveting technology for structural components

- development of in-line plasma treatments

WPC- Injection Molding

- fill behavior of WPC as a core component in sandwich-molding

- back-injection molding of wood veneers with WPC

Injection Molding – Direct Compounding

- product-specific material development

- fiber-reinforced plastics

Injection moulding of short and long fibre-reinforced plastics makes it possible to produce components with good weight-specific properties in high volumes. Since standard injection moulding machines can be used to process fibre-filled compounds, it is a widely used manufacturing process in the industry. However, in the processing procedure there is a high shear input, especially during the plasticising process, which leads to fibre breaks and a decrease in fibre lengths. The problem is that the mechanical properties of fibre-reinforced plastics, such as stiffness, strength and impact resistance, are strongly dependent on the fibre length present. The reason for this is the improved force transmission between fibre and matrix material with an increase in fibre length. In the injection moulding process, the aim is therefore to be as gentle as possible on the fibres in order to minimise fibre length degradation. The fibre damage occurring in individual cases in the injection moulding process is difficult to estimate due to the many influencing factors, which means that an exact prediction of the component properties and the implementation of a component design are only possible to a limited extent.

The aim of the research project is to develop a fibre breakage model that describes the fibre length reduction occurring in the plasticising unit as a function of the machine, process and material parameters. The basis for this is formed by extensive experimental investigations, with which the fibre length reduction along the screw channel is determined for different materials and machine sizes. The results provide insights into the extent to which process parameters such as back pressure or metering speed influence fibre damage. By means of dead-stop investigations, the influence of the melting behaviour on the fibre damage can also be examined. By considering different screw geometries and materials, a comparison of the results can provide important insights into the damage mechanisms that occur. Based on the experimental findings, an analytical model will be developed to describe the fibre length reduction along the plasticising path.

The aim of this research project is to generate improved and cost-effective new material surfaces by further developing existing powder coating systems in combination with an innovative process technology of direct coating in the injection mould. This enables a cost-effective and ecological coating of plastic injection moulded components. To enable direct coating, an in-situ coating process for the injection moulding process is being developed at Kunststofftechnik Paderborn, in which the thermoset powder coating is applied in the mould during moulding. This achieves a time and cost advantage compared to external coating. The powder is applied to the already heated cavity via a Corona powder gun that enters the open mould. The powder gun is then moved out of the parting line by a linear robot and the mould closes. The powder coating melts, starts to cross-link and a continuous coating layer adhering to the mould wall of the cavity is formed. After a handling time, the plastic melt is introduced into the cavity and the lacquer layer is injected underneath. After the remaining cooling time, the finished painted component is ejected.

A frequently used process for improving the adhesive strength of multi-component, incompatible systems is surface pre-treatment using plasma technology. Application areas for the use of plasma in the further processing of plastics are bonding, printing, painting and 2K injection moulding.

Within the research project, the InMould Plasma process is to be developed for the surface pre-treatment of large-area plastic components in the 2-component injection moulding process. The aim is the homogeneous surface activation of the pre-moulded part in the injection moulding process. The plasma treatment is integrated in a multi-component injection mould. In the first injection moulding station, a square plate is moulded and remains in the nozzle side. A sliding table moves the second station, the plasma station, in front of the previously moulded plate. The surface activation now takes place partially in the exposed areas in the form of a snake geometry. After opening the mould again, the second component is sprayed onto the functionalised contact surfaces of the base plate in the third station.

Further goals of the research project are the expansion of material combinations, especially in the area of hard/soft, the homogeneous treatment of 3D surfaces and components of multiple moulds.

Due to the progressive development in the field of alternative drive concepts (hybrid concepts, e-mobility) for motor vehicles and the associated high demands on the materials used (especially for components in the engine compartment), the use of 2-component composite materials made of thermoset and elastomer is the better alternative compared to thermoplastic or metal-elastomer compounds.

The aim of this research project, which was carried out in cooperation with the German Institute for Rubber Technology e.V. in Hanover, is to investigate the production of 2-component composite test specimens made of thermoset and elastomer on the basis of different material combinations and to achieve sufficient composite adhesion for the application while complying with required specifications. By optimising the formulation and process in the manufacture of the 2-component composite test specimens, the composite adhesion has been significantly improved.

In the production of moulded plastic parts in extrusion and injection moulding processes, the quality of the components is essential. This is particularly true for components made of engineering plastics such as polycarbonate (PC). With this material, the purity of the manufactured product must be ensured. However, when processing polycarbonate, long contact times with metallic surfaces result in reciprocal, near-surface degradation. The resulting damage can lead not only to a reduction in the service life of tools and screws, but also to an increase in the number of rejects produced. Furthermore, degradation of the plastics used in the form of molecular degradation can impair the quality of the components produced in terms of optical purity and mechanical properties.

In the degradation of plastics, a distinction is generally made between chemical and physical ageing. Specifically for the material PC, chemical ageing occurs during processing and is associated with chemical degradation. One factor for chemical degradation is the water content or the water absorption capacity of the plastic. In the case of PC, the saturation state is reached at a relative humidity of 100% and room temperature (23°C) at approx. 0.3% by weight. If the water contained is not removed before processing, this leads to a degradation of the molecular chains at the increased temperatures and pressures during plasticisation.

Consequently, the primary objective in this research project is to gain an understanding of the degradation processes during the processing of polycarbonate, with a particular focus on the reciprocal influence between the polymer and the mould material. Special attention is given to the water content of the processed polymer and its influence on degradation. This is done both on a molecular level based on basic research and on a macroscopic level in the processing process.

Plastics are playing an increasingly important role in the substitution of metallic materials. Due to the low material costs of BMC compared to high-performance thermoplastics as well as the processing in the injection moulding process, high-strength and shrinkage-free components with low weight can be produced cost-effectively in almost any geometry.

The aim of this research project is to develop a fibre damage model that maps the material-specific influences in the injection moulding process of BMC moulding compounds (material composition, process parameters and screw geometry) on fibre length reduction. During the processing of BMC moulding compounds in the injection moulding process, the added long glass fibres with an initial length of 3 mm to 12 mm are significantly shortened due to the dissipative input in the processing procedure, which leads to a reduced utilisation of the material potential.

To validate the model, the calculated fibre lengths from the developed BMC fibre damage model are compared with the fibre lengths actually determined. For this purpose, dead-stop investigations are used to determine the fibre damage via the screw conveyance of the suspension. To check the fibre length reduction, samples are taken at defined points in the screw conveyance and examined by means of fibre length scans.

Taking into account the main influencing factors on fibre damage shown in the model, a fibre-protecting process technology is developed and put into operation. Finally, the real fibre damage is examined and compared with the calculated results of the model.

In the development of the novel process technology, compatibility with common BMC injection moulding machines must be ensured in order to give BMC processors access to the new technology of the two-piston injection moulding unit.