GITBlow

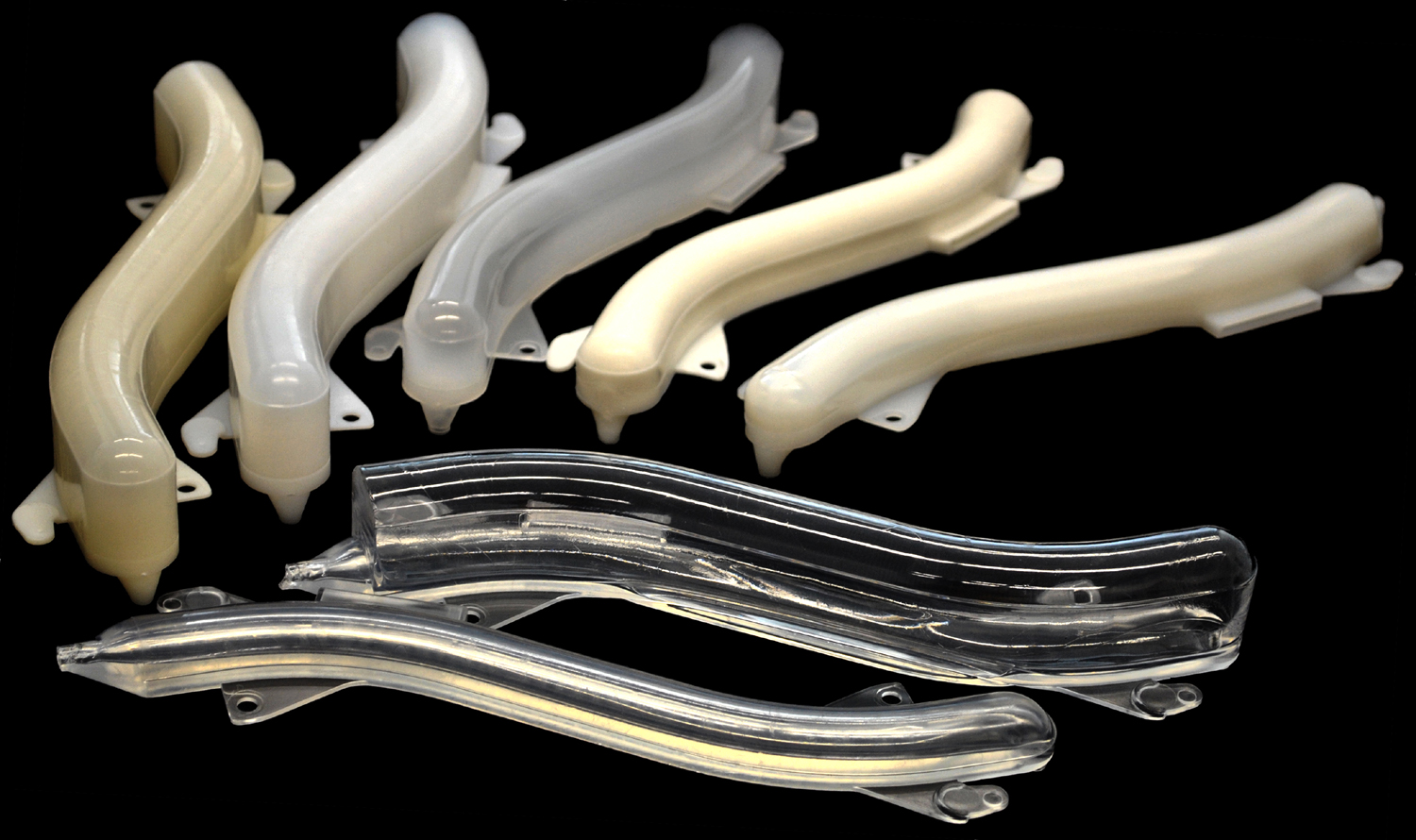

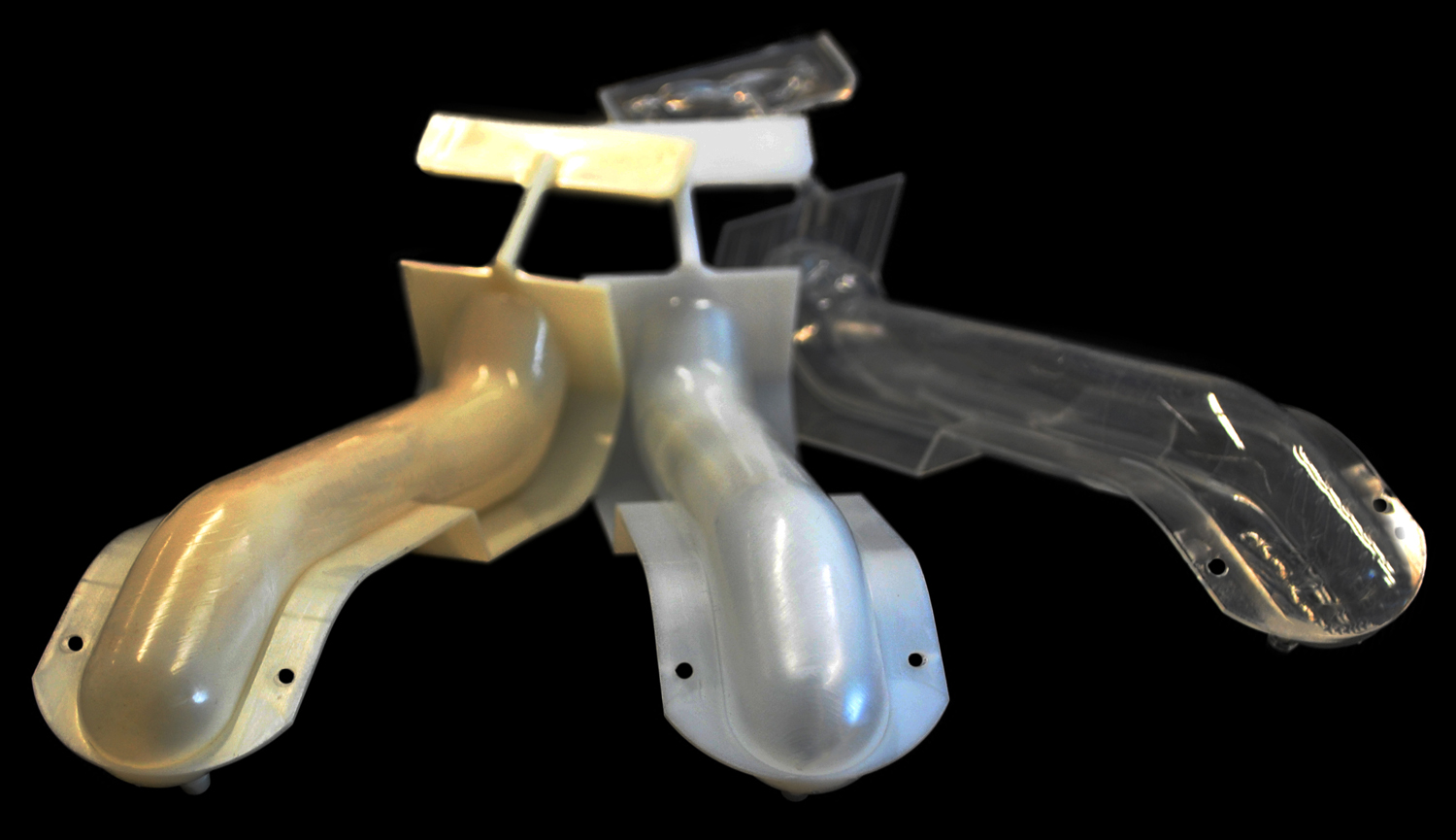

The specific type of injection molding procedure known as GITBlow is a combination of gas-injection and blow molding. With this process, complex plastic components can be produced directly with hollow regions possessing large cross-sectional areas, a large hollow-body volume, and, optionally, lower wall thickness. The primary goal of the process is the integration of functional cavities (for example for cable routing or transport of media), without requiring an elaborate multistage production process, such as welding or adhesive bonding of molded or blow-molded components.

Using prototypes produced similarly to series parts, different aspects of this process are being investigated by the Kunststofftechnik Paderborn with the goal of adjusting component properties; the areas being researched include:

- influence of process parameters

- integration of variable temperature-control methods

- process simulation by means of CFD and FEM

- processing of specific materials

- development of hybrid structures

The importance of lightweight component structures is becoming increasingly important in industrially manufactured products. Price increases for natural resources are also forcing industry to use raw materials more efficiently. The special injection moulding process GITBlow developed at Kunststofftechnik Paderborn can contribute to this through innovative process control. It allows the production of hollow and particularly lightweight structures characterised by large-volume, complex cavities and low wall thicknesses.

The aim of the project described here is to simulate and model the process behaviour during the processing of semi-crystalline plastics in the two-stage GITBlow process. Previous results have shown, based on the processing of amorphous materials, that in the simulation of the GITBlow process a division into the three characteristic process steps of the process is target-oriented. These are preform production by means of gas injection moulding (simulation CFD), temperature equalisation by heat transport (simulation FEM) and inflation by means of a second gas injection (simulation by means of a spring-damper model). Using semi-crystalline materials, PP; PA6 and PA12 have already been simulated and experimentally validated. Finally, the focus is on implementing the crystallinity properties in the modelling.