Sustainability & circular economy

The transformation to a sustainable and resource-efficient plastics industry is a key challenge of our time. At Kunststofftechnik Paderborn (KTP), we are working to help shape solutions for this in a scientifically sound and practical manner.

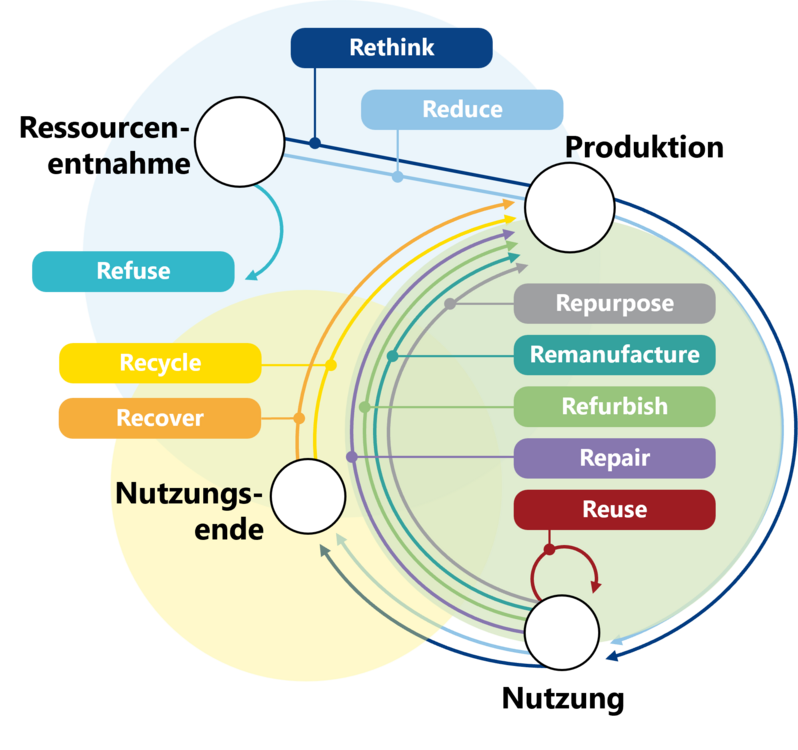

One focus of our research is on the R-strategies of the circular economy: reduce, reuse, repair and various recycling approaches - mechanical and chemical. These principles form the basis for a large number of projects in which we research innovative technologies, material cycles and application scenarios.

In addition to our basic research, we also realise application-oriented cooperation projects with industrial partners. If you have any further questions about sustainability, please do not hesitate to contact us!

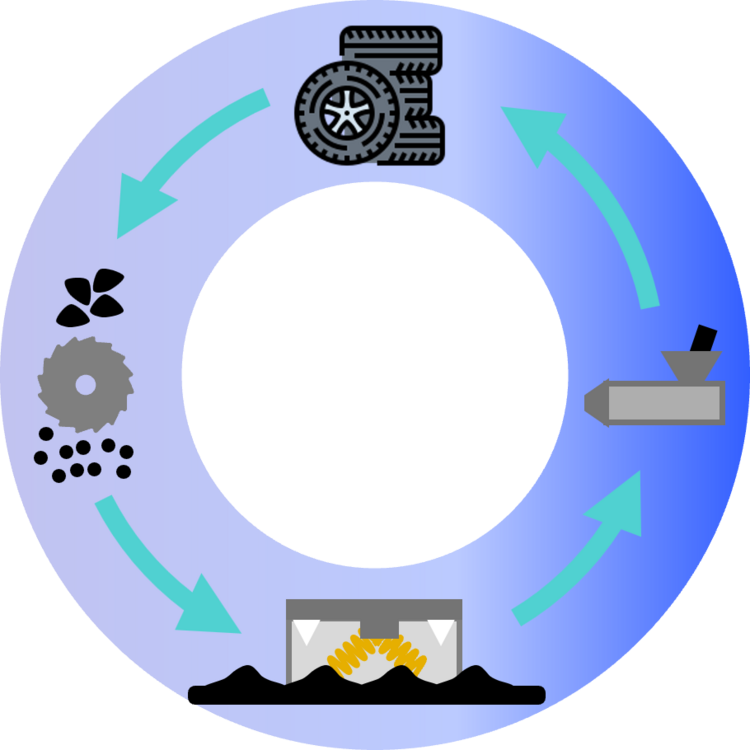

DevEl - Microwave-based devulcanisation of sulphur-curing elastomers

The aim of the project is to develop an energy-efficient microwave system based on semiconductors that can be used to recycle sulphur-crosslinked elastomers such as used tyres - to significantly reduce CO₂ emissions and return valuable raw materials to the cycle. The project includes, among other things

- Material characterisation

- Development of the devulcanisation unit

- Process validation and material evaluation

- Revulcanisation and cycle integration

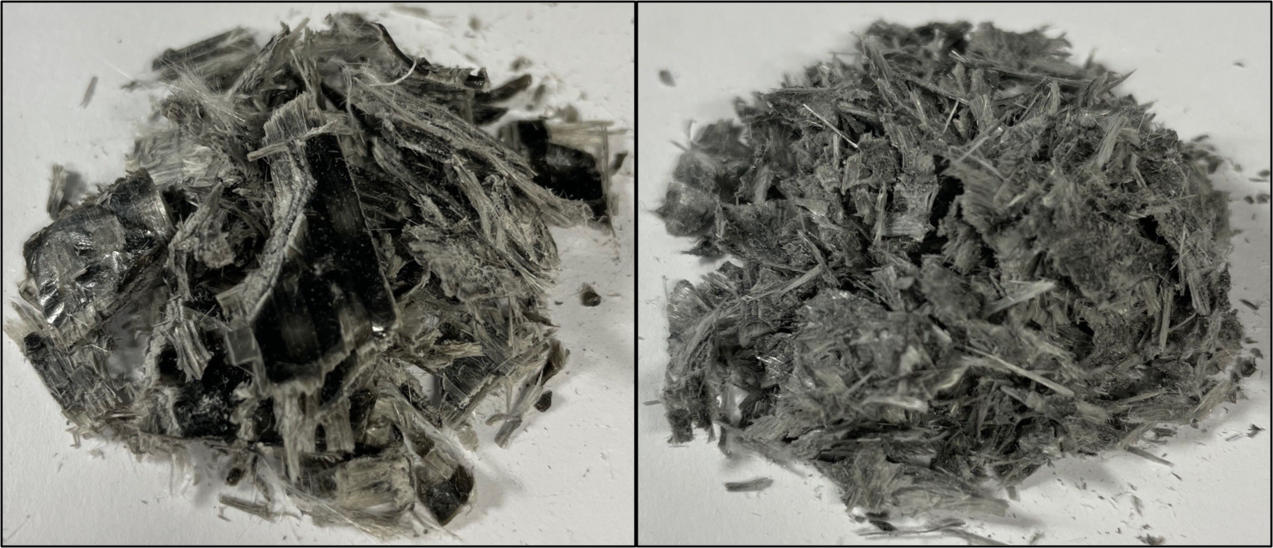

Modelling of recycled organic sheets

The aim of the project is to model the resulting fibre length after the plasticising process in the injection moulding process when recycling organic sheets. Thanks to their excellent weight-specific properties, these contribute to the reduction of greenhouse gases in the mobility sector, among others. Recycling is intended to counteract the increasing demand for raw materials and enable them to be returned to the material cycle. The project comprises the following core aspects:

- Shredding of organic sheets

- Investigations into fibre dispersion, homogenisation and length along the plasticising path

- modelling

- Model validation

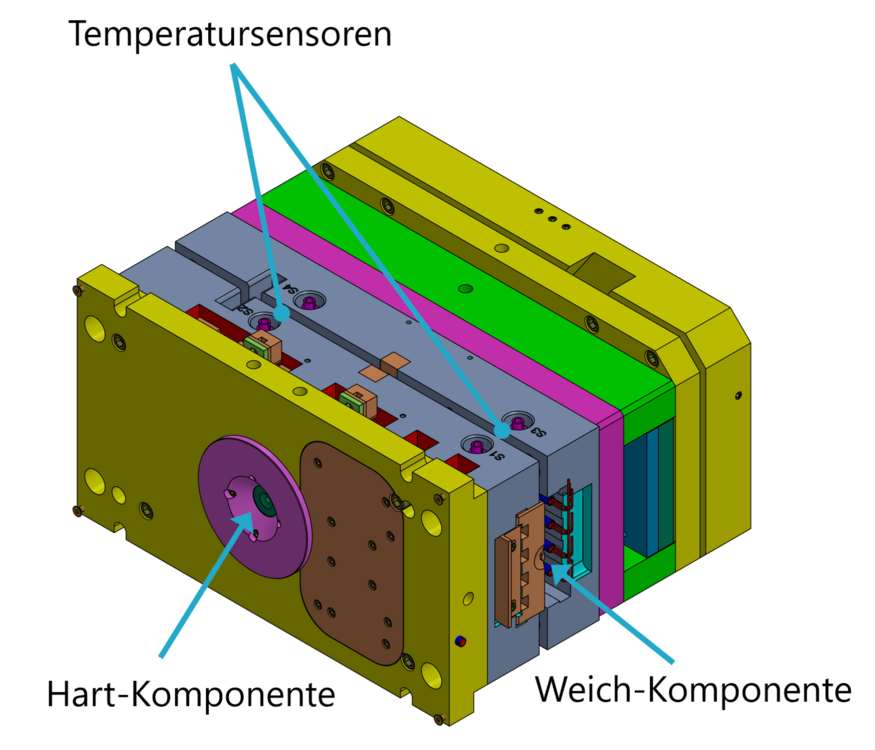

2-component direct adhesion - improving the bond strength of elastomer-thermoset systems

The aim of the project is to develop a single-stage 2-component injection moulding process for the production of high-adhesion hard/soft composite components. In line with the Reduce principle of the circular economy, we are pursuing the goal of avoiding adhesives, mechanical joining processes and additional production steps by integrating functions. Instead of laboriously joining individual parts, we rely on direct adhesion in the single-stage injection moulding process - this saves energy and material and improves resource efficiency. The core aspects of the project are

- Material modification

- Process development in 2K injection moulding of thermoset elastomer systems

- Experimental investigations of the process with a focus on composite adhesion and interfacial reaction

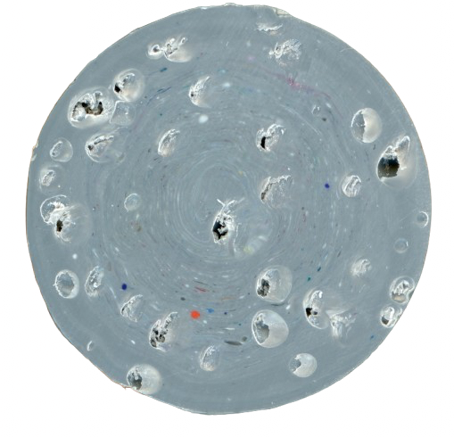

AI-con - AI-supported processing of polyolefin post-consumer recyclates

The aim of the project is to develop a first prototype of an AI-supported process control system for processing polyolefin regrind from the PCR material stream. In line with the Reduce principle, the regrind is to be processed directly in order to avoid energy-intensive processing steps and thus increase the ecological efficiency of recyclate use. The main challenge here is handling inherent material variability, such as fluctuations in composition, contamination and the non-uniform particle shape of the regrind. Process anomalies are to be detected and corrected by means of cascaded process control based on the characterisation of the melt in the screw antechamber and downstream optical component control. The project includes

- Development of a simulation model to map the behaviour of PCR

- Development of a training data set for the AI

- Experimental investigation and validation

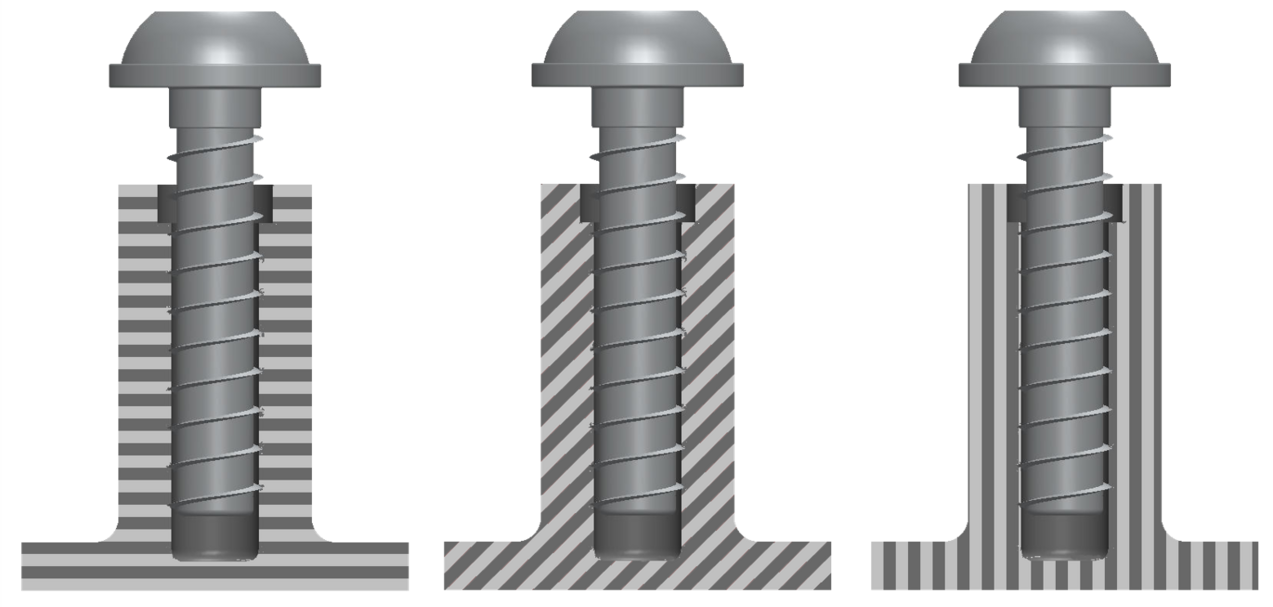

Direct screwing of additively manufactured plastic components

The aim of the project is to develop initial design and application recommendations for the direct screwing of additively manufactured plastic components. A transfer of existing guidelines for injection-moulded thermoplastic components is not possible due to the layer structure and the derived direction-dependent properties. Direct screwing allows highly functionally integrated additive components to be joined with assemblies, thus saving material and components. In addition, the direct screw connection is detachable, making maintenance, repair or replacement easy, which also contributes to sustainability. The core aspects of the project include

- Identification of the framework conditions

- Investigation of the screw-in behaviour

- Analysis of the short-term strength & preload relaxation

- Definition of design recommendations

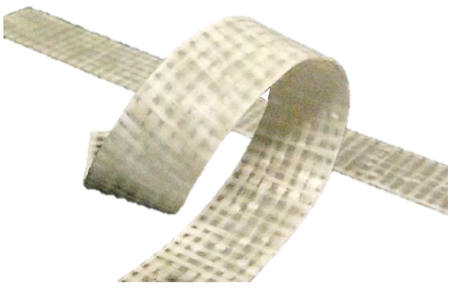

FlexGuard - Adhesive-based joining of highly flexible TPE organic sheets

The aim of the project is the development and adhesive joining of highly flexible organic sheets made of TPE materials. The TPE organic sheets are to be used as reinforcement and repair patches for system and structural elements. The reinforcement eliminates the need for multiple components, overdimensioning or the use of heavy/stiffer materials, thus saving resources. Using the patch as a repair kit can increase the longevity of components. Previous reinforcement and repair solutions, such as DU tapes, are very stiff and inflexible, which means that beading, undercuts or edges cannot be reinforced. Flexible TPE organic sheets are intended to eliminate these disadvantages. The key points of the project are

- Production of suitable fibre-matrix combinations

- Investigation of bonding suitability

- Demonstration of the reinforcing effect

- Analysing the suitability as a repair patch

Material recycling of used plastic powder from powder-based additives Manufacturing process using the FDM method

The aim of the project is to recycle the used powder from the PB-AM process into plastic filament that can be processed in FDM. This should avoid the disposal of the material and conserve natural resources. Key aspects of the project are

- Material characterisation of the used plastic powder

- Filament production and characterisation

- Investigation of suitability for processing in FDM

- Derivation of guidelines for the recycling process

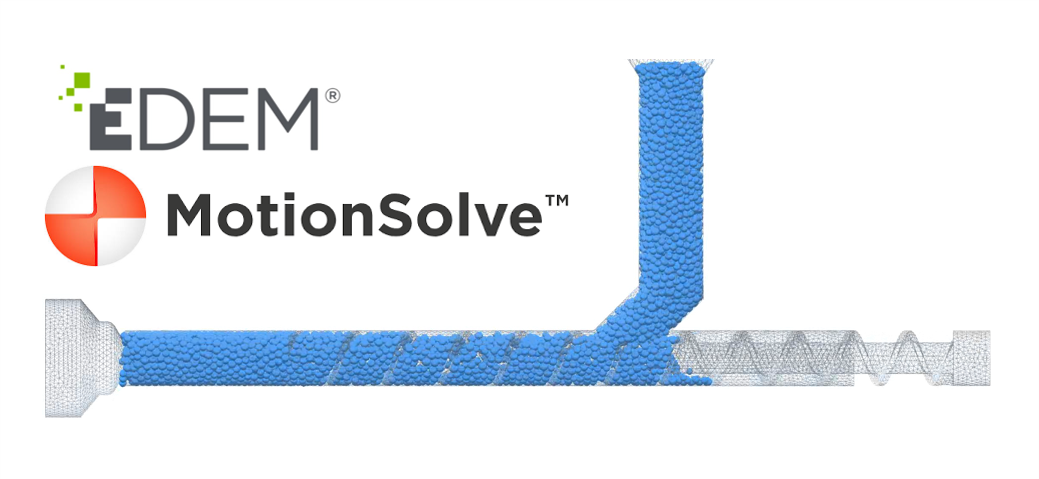

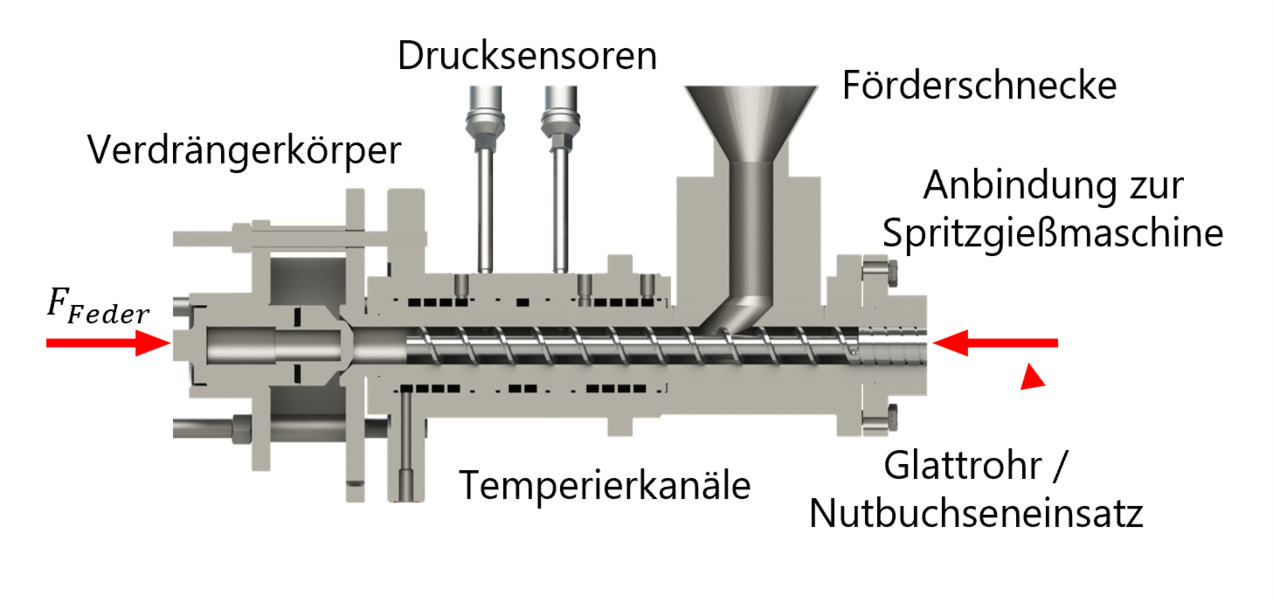

Unsteady solids conveying

Particularly when processing challenging materials such as untreated regrind from recycling processes or granulate with lubricant additives, the feeding and conveying of the loose bulk material at the start of the plasticising screw has a major influence on the overall process. An inadequately dimensioned feed zone can impair the efficiency of the process and the quality of the manufactured components due to bridging in the hopper or air being drawn in. The aim of the project is to use numerical simulation to gain a deeper understanding of the processes in the feed zone of injection moulding machines and to create corresponding design options. Sub-aspects are

- Development and validation of a numerical simulation model for injection moulding processes based on the discrete element method (DEM)

- Modelling the influence of grooved feed zones for processing materials with low feed rates

- Development of an improved feed geometry for processing regrind and flakes