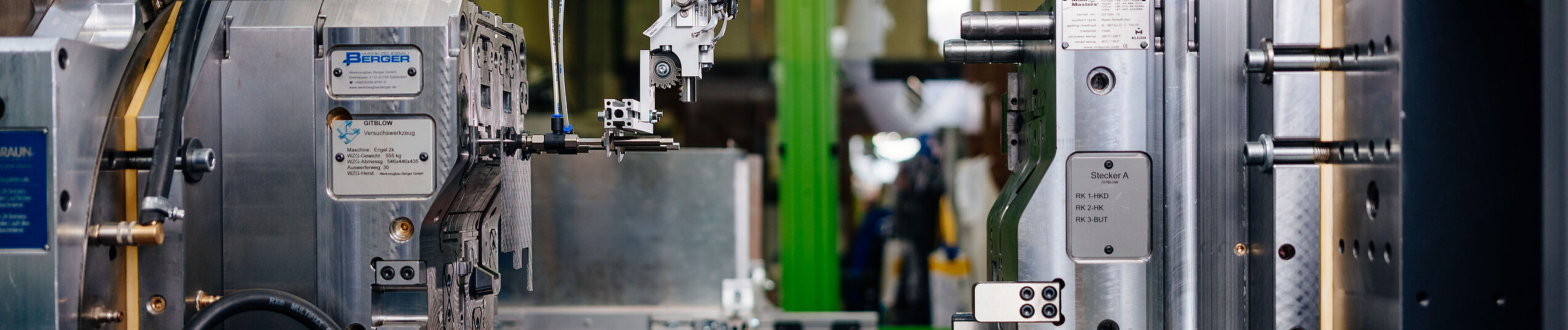

Injection moulding

Kunststofftechnik Paderborn has been involved in injection moulding, which alongside extrusion is the most widely used plastics processing method, since its foundation. In addition to the conventional 1-component injection moulding process, research is being conducted into the special injection moulding processes of 2-component composite injection moulding, sandwich injection moulding, gas injection technology (GIT) and the GITBlow process developed at KTP. In addition to the process technology of injection moulding, our areas of activity also focus on filling behaviour in the mould and on mould technology.

Tool technology

- Development of coatings to reduce demoulding forces

- Development of spray riveting technology for structural components

- Process engineering development of inline plasma treatment and powder coating