Single- / Twin-Screw Extrusion

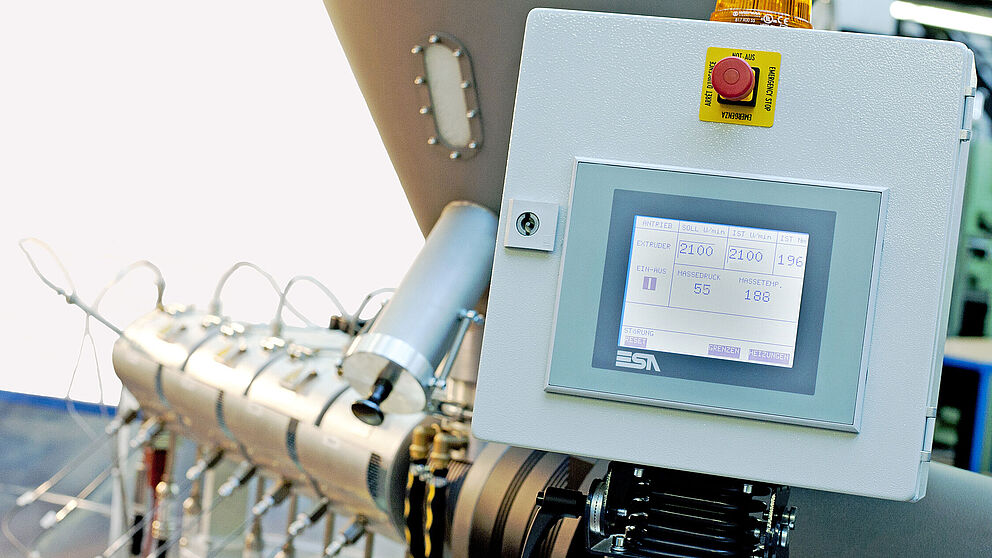

In the field of process engineering design of screw machines, KTP offers you a wide range of services in the area of single-screw and twin-screw extruders. Our wealth of experience ranges from rubber extruders and classic polymer extruders for polycarbonate etc. to high-speed extrusion or the design of compounding extruders.

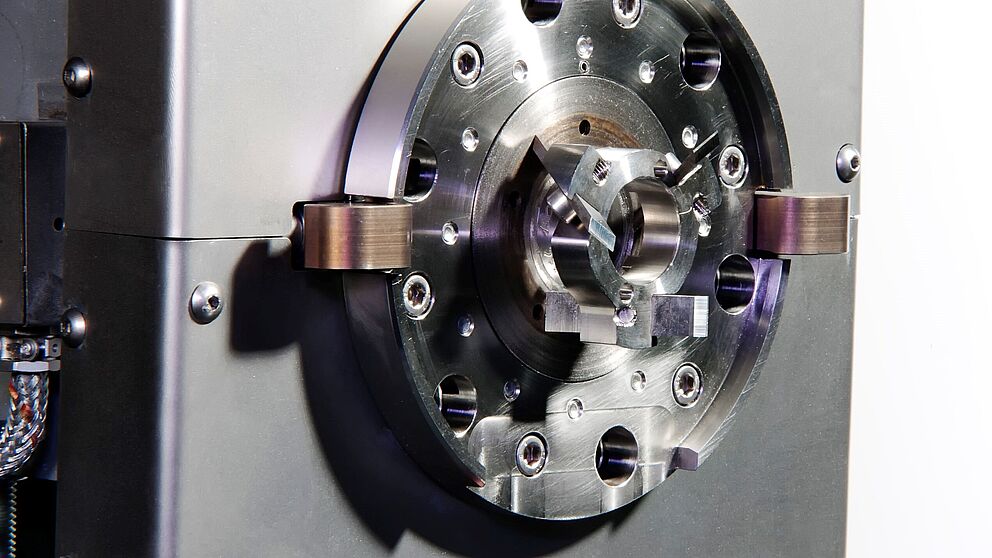

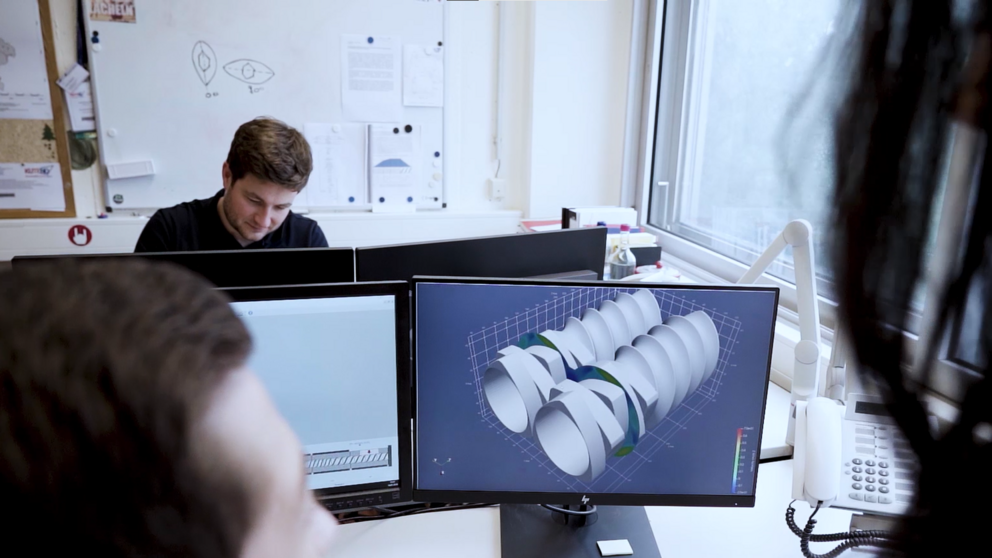

One of our core competencies is screw design. We have already designed screws for a wide variety of applications in this area. In addition to this accumulated knowledge, the KTP can draw on the REX or SIGMA simulation software to respond individually to your machine/material/process parameter constellation.

The institute will also be happy to help you make your process more energy-efficient. There are various approaches for the design of the screws, the drive or the heating zones. Our optimizations are based on empirical studies, but also on simulations and calculations, for example.

In addition to the services mentioned above, we also support you with your individual problems. We look forward to your inquiry.

Features in SIGMA

Plasticizing unit Injection moulding machine

Problems with mechanical or optical properties often occur during the manufacture of injection molded products. The obvious first step is to look for the cause in the injection molding cycle or in the tool used. The KTP will help you troubleshoot and develop an optimal concept for your requirements.

Another important aspect is the plasticizing unit, which, if incorrectly designed, is often the cause of the above-mentioned impairments. Specifically, this can involve solid inclusions or color differences. By analyzing the melt homogeneity, the institute can advise you on the design of the plasticizing unit. As a software tool, the engineers use the in-house application PSI, with which all necessary design parameters can be simulated, analysed and then the geometry of the screw can be optimized. In addition, the design can be verified by a series of measurements in the processing laboratory, for example.

Do you have any further questions or need help with another problem? Then contact us, we look forward to hearing from you.

Process engineering design of screw machines

For interested companies, Kunststofftechnik Paderborn offers the process engineering design of screw machines using its in-house REX/PSI and SIGMA software. In addition to the new design of screw machines according to the customer's requirements, existing processes can also be recalculated and geometric and process parameters optimized. Material measurements are also offered for this purpose so that the design can be based on realistic data.

Furthermore, a scale-up / scale-down of existing screw machines can be carried out so that an already functioning process can be transferred to a different screw diameter. This process can be used to create a screw catalog at the customer's request, which depicts different sizes of a screw machine series with the desired process characteristics.

In addition, the design / optimization of a screw machine includes the preparation of a report containing the initial situation, the design, the results and a summary.