Technical advice

Thanks to our many years of research work in plastics technology, we are able to offer expert advice on a wide range of issues. In addition to the standard processing methods of extrusion (single screw and twin screw) and injection molding, we have been involved for years in the development of special processes, the processing and recycling of fibre composites, the integration of joining processes into the injection molding process and, last but not least, the joining methods of welding, bonding and mechanical joining.

We are happy to provide advice on the

- Evaluation of manufacturing processes

- process design of screw machines

- Comparative evaluation of processes for a specific application

- Analysis of damage

- ...

Technical advice is often accompanied by investigations and analyses in our laboratories.

Implementation of small projects

For individual questions in the field of plastics technology, we offer the implementation of small projects. These can be investigations in our laboratory with small or large-scale tests, simulations, feasibility studies, sampling or special developments (e.g. for injection molds).

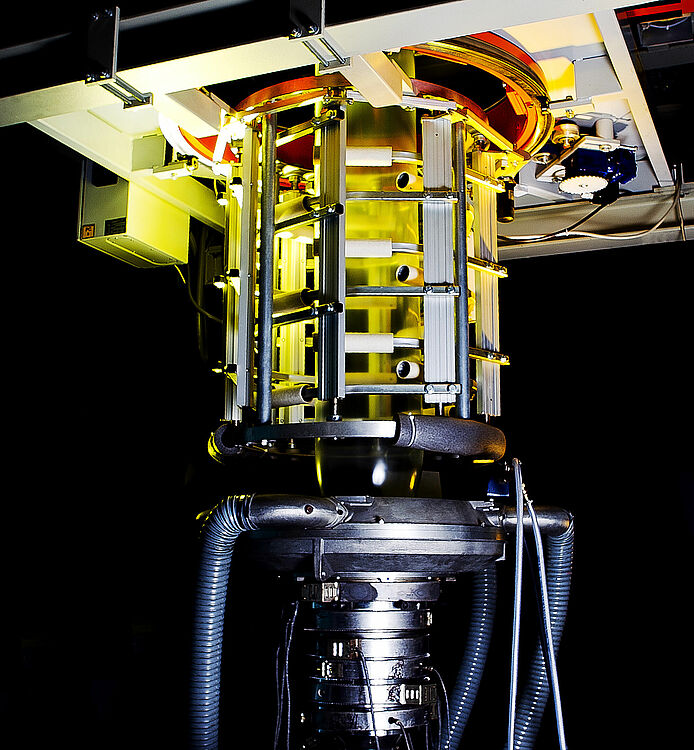

We can carry out experimental tests or develop and set up new processes in the fields of welding, extrusion and injection molding thanks to our extensive plant technology. Our welding laboratory reproduces all common welding processes so that a process comparison can be carried out for a specific application.

Innovative tool concepts and special injection molding processes have been an integral part of Kunststofftechnik Paderborn's research portfolio for many years. We are also available to support new developments in this area.

It is often possible to apply for public funding for more extensive projects. We are available as a research center for bilateral or multilateral projects and provide support in preparing the application documents and selecting the funding body.

Individuelle Schulungen

Kunststofftechnik Paderborn offers interested companies training courses for the further education and training of their employees in the field of plastics technology. Together with the company, a training concept is developed that is tailored to the needs of the employees. For example, technical sales staff are trained differently to machine operators or process developers in terms of the content and depth of the topics.

The scope of the training can vary between one or several days. We are happy to combine theory with an integrated practical part, which takes place in the laboratories of Kunststofftechnik Paderborn.

Possible topics for training courses could be

- Materials science of plastics

- Fundamentals of extrusion technology

- Designing screw machines with REX/PSI or SIGMA software

- Fundamentals of plastics joining technology

- Bonding of plastics

- Welding of plastics (basics, welding processes, design of welding processes, ...)

- Basics of injection molding technology

- Recycling of plastics

- Special injection molding processes

- Fundamentals of rubber technology

- Fundamentals of rubber processing

- Fiber composite plastics

- Design of experiments

We respond to the ideas of the companies and integrate special topics into the training on request.

Ansprechpartner

Dr.-Ing. Florian Brüning

Plastics Technology and Plastics Processing

Pohlweg 47-49

33098 Paderborn